Product

Our Products

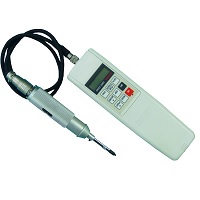

• This machine is for measuring the tightening force of bolts in accordance to JIS B 1084 testing requirements.

• Tightening Axial Tension Force (Ff), Tightening Torque (Tf), Bolt Threaded-portion Torque (Ts), Tightening Rotation Angle and Extension can be measured.

• Testing speed of 30RPM can also be set as per ISO 16047 requirements.

• A tester with intelligence. It computes the angletorque Etc. parameter, thus achieving precision results.

• The MAX series is a load tester with built-in USB Drive in it. Through this facility, you can store and save your job more conveniently

• You can see the test results and curve of torque/angle on the high density LCD on the MAX tester and also the built-in printer can print out. The CENTRONICS INTERFACE (RS232C) enables outside printer to print test results out in form of test report.

• Single column tester maximum structure capacity is 2kN (200kgf) with effective stroke up to 1.2metre.

• User can specify stroke of 600m or 900mm or 1200mm and also choose their desired loadcell capacity.

• Basic models come with built in rotary encorder of 0.01mm resolution & Special model with 0.001mm for the displacement.

• Optional elastometer and grips can also be installed to check elongation {eb9cfd4e3b516869cb839b8b2c338ebd16b99827caa87fe8648376116c5dd92c}.

• For simple torque testing for checking tightening force of fasteners.

• Bit on the market can be used as it is equipped with 6.3mm hexagonal bit.

• LEAF-5000 is a high capacity leaf spring tester, mainly use in the automotive industries for trucks and lorry.

• Tester able to preset distance to find the load and also preset the deflection of leaf spring to find load.

• Software program is available to enhance the testing with data and testing condition storage.

• Compression and Side Force Spring Tester is a new and innovative machine that is develop from our spring testing machine over the years.

• There will be three load cells above and under the compression and an additional three load cells for the XY axis, using 9 load cells for total compressive load on proprietary software, to obtain displacement force from the top and bottom moment of the spring with reference to the center.

• All data can be collected in a single using this Compression and Side Force Spring Tester

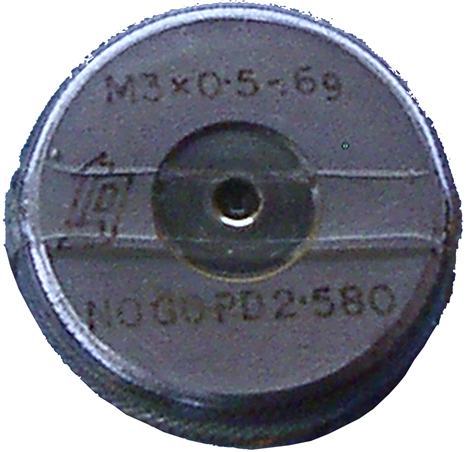

• All screw plugs gauges

• All special screw rings

• All plain plug gauges

• All plain ring gauges

• All taper screw plug gauges

• All taper screw ring gauges

MicroLabo and *MicroLabo Lite are advanced measuring Software compatible with DS-3 Series.

MEASURING

Measured data can be paste onto the image and export to Excel spreadsheet for reporting.

CALIBRATION

Both software enable a Accurate and Speedy calibration due to auto calibration.

Calibration is done by capturing the glass scale (standard shipped) at high magnification rate, and calculating it either manually or automatically.

• Measure a distance between 2 points.

• Marker of any color and size of your selection can be drawn on live or still image.

• Images can be saved under JPEG or BMP files.